Roll-up cover for vertical application

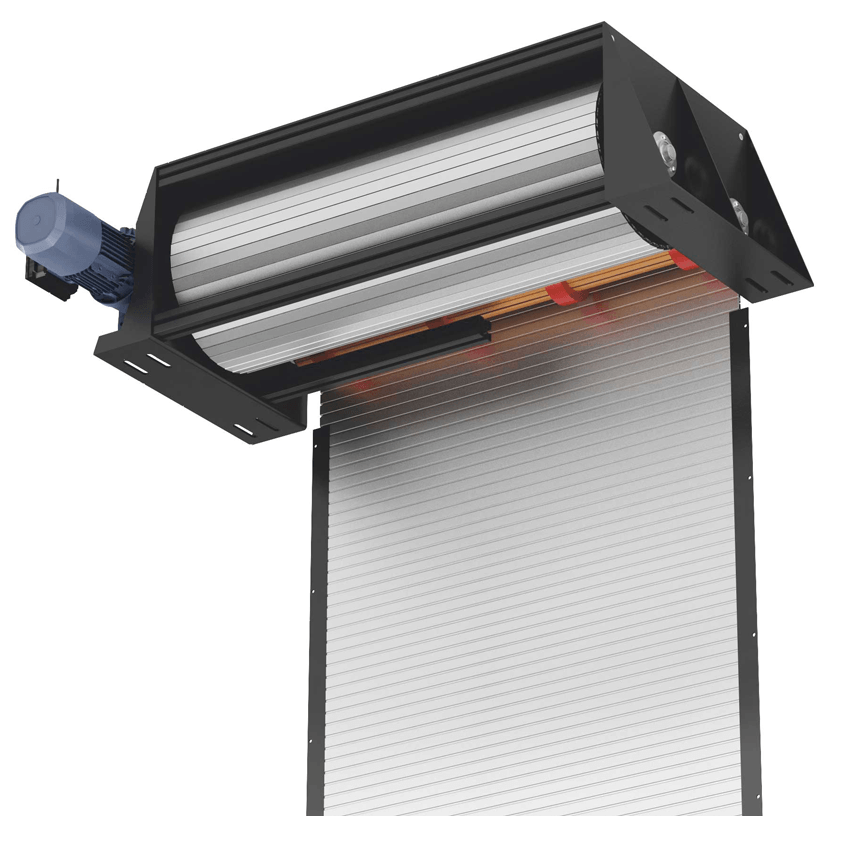

MOTOR ROLL-UP COVER

Roll-up cover for vertical application

All P.E.I. apron covers can be equipped with a motor and serve as a dividing wall between the working area and the machine operator. This allows fast changing of the tool or the workpiece.

The apron cover works in a vertical position and can be designed with or without canister. The motor can be installed on the left or the right side, vertically or horizontally.

Our technical office is at your complete disposal for any questions.

Drop Aprons

Aprons for tool change

Aprons for pallet change

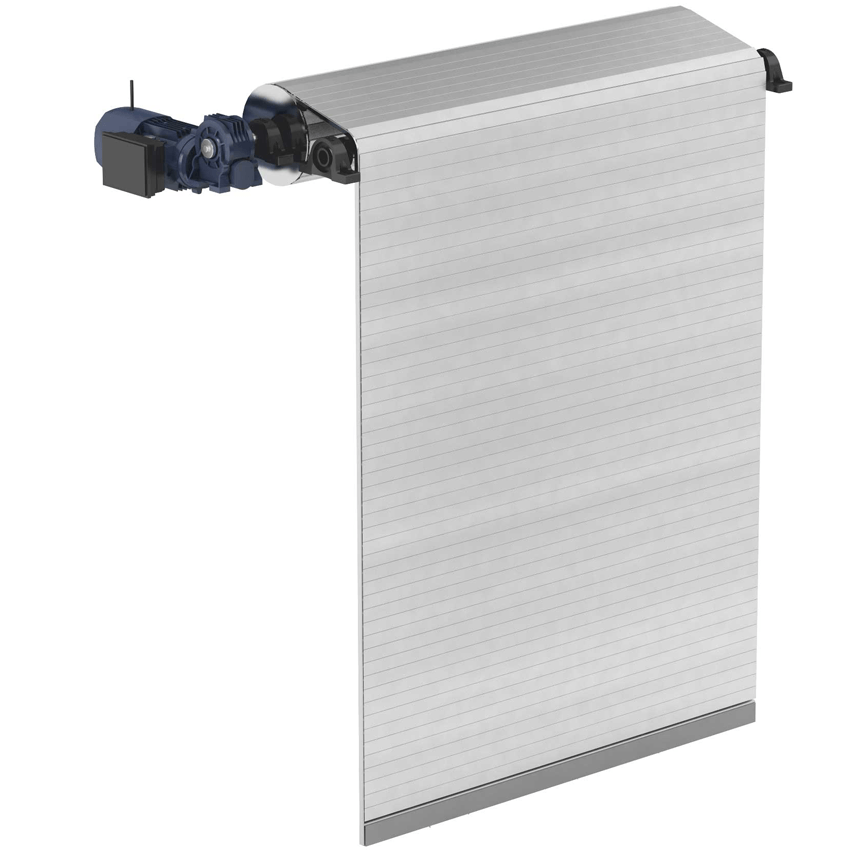

Extruded Drop Apron Covers

They are extruded aluminium apron covers dedicated to general mechanics. They allow the separation of compartments to prevent access to dangerous or restricted areas.

The most suitable profile is selected from the “J” or “AKS” range according to the size and specific application.

Our technical office is at your complete disposal for any clarification.

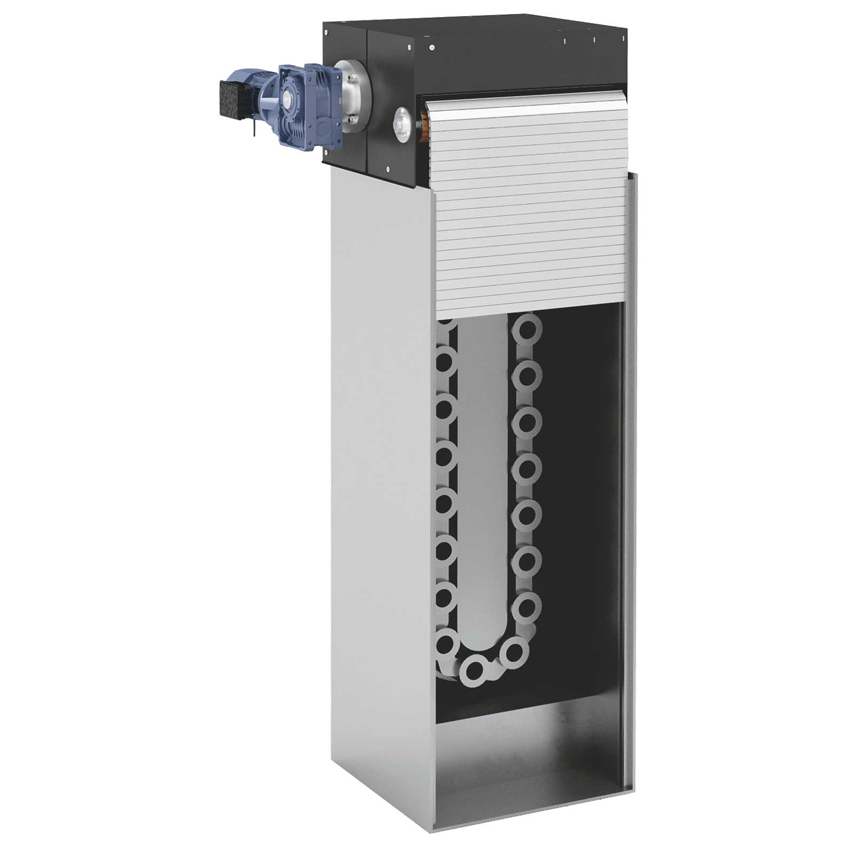

Apron Covers for the tool change

These apron covers are suitable for separating the work area and the tool change area (or head change).

They are characterised by their resistance to chips, coolants and in some applications also to breakthrough according to the current regulations.

They are typically selected from the “J” range and are more compact than movable door closures thanks to the roll-up apron system. The opening speed is a design parameter in agreement with the customer.

Our technical office is at your complete disposal for any clarification.

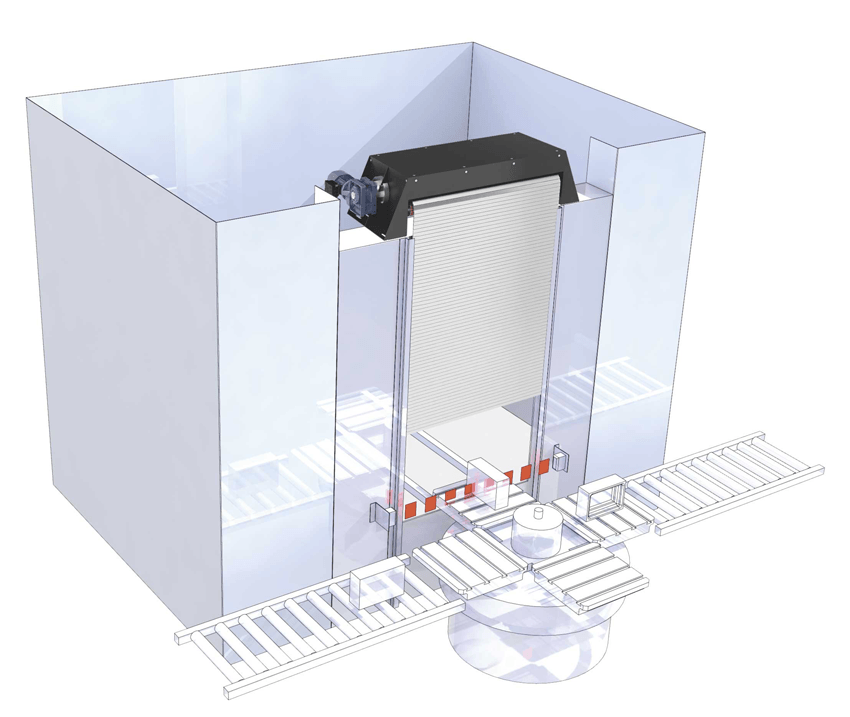

Apron Covers for pallet change

The roll-up apron covers for pallet changing are a compact and fast alternative to sliding doors. Compared to vertical sliding doors, the advantage of rolling up the apron covers allows for a minimum space requirement above the pallet area where bridge cranes typically move.

The advantage compared to side sliding doors is that it does not have any encumbrance beyond the apron cover guide. This allows you to build many more compact transfer lines.

The apron covers are resistant to all mechanical processes including chip removal and laser welding.

Our technical office is at your complete disposal for any clarification.