Thermic-welded tight bellows

Thermic-welded tight bellows

They are used when leak-tight protection of the components (i.e. screws, shafts, etc.) is necessary

against the contamination made by coolants.

They have good chemical and heat resistance according to the properties of the materials used. Thermic-welded tight bellows are available in various shapes and dimensions.

Small tooling costs for new moulds should be considered, if not already available in stock.

Data

Standard materials

Formulae

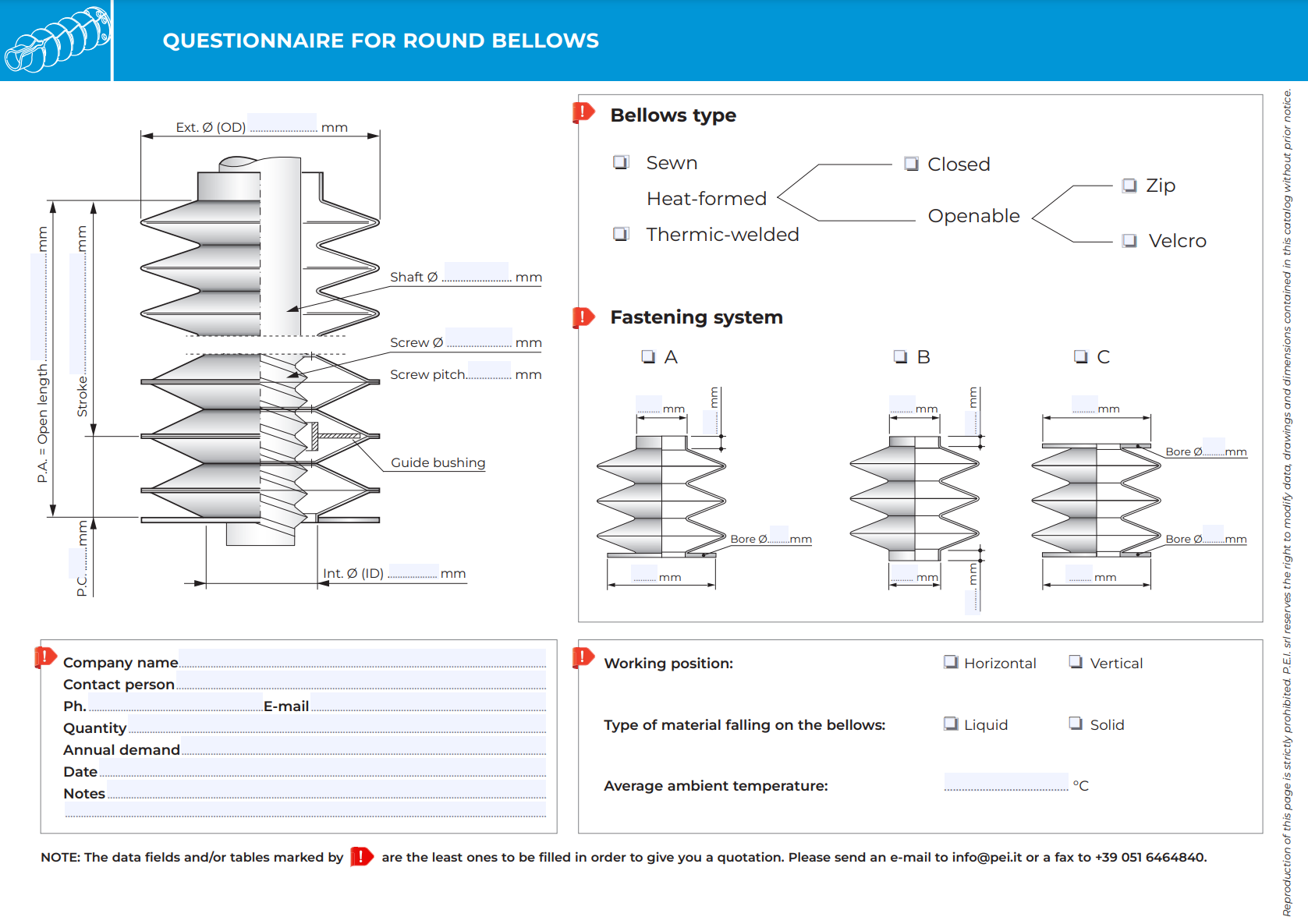

Questionnaires

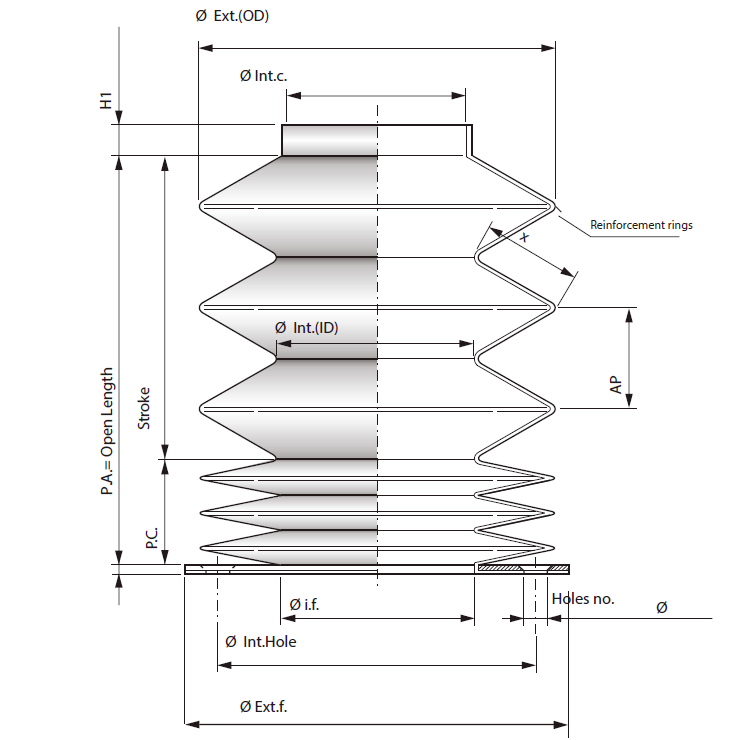

Type A fixing schemes

Bellows with the type A fastening system have with collar and a flange

Bellows data:

Ø e. soff. = Circular bellows outer diameter

Ø i.c. = Internal collar diameter

Ø i. soff. = Bellows internal diameter

Ø i.f. = Internal flange diameter

Ø int. holes = Flange hole centre-to-centre diameter

Ø e. f = Flange outer diameter

P.A. = Open length

P.C. = Closed length

Stroke = P.A. – P.C.

AP = Open step

X = Bellows fold height

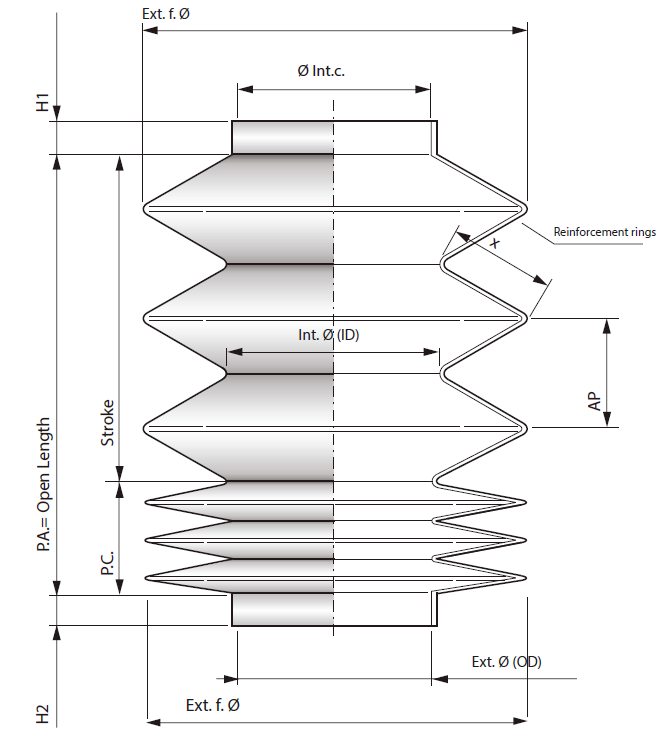

Type B fixing schemes

Bellows with type B fastening system have two collars

Bellows data:

Ø e. soff. = Circular bellows outer diameter

Ø i.c. = Internal collar diameter

Ø i. soff. = Bellows internal diameter

P.C. = Open length

Stroke = P.A. – P.C.

AP = Open step

X = Bellows fold height

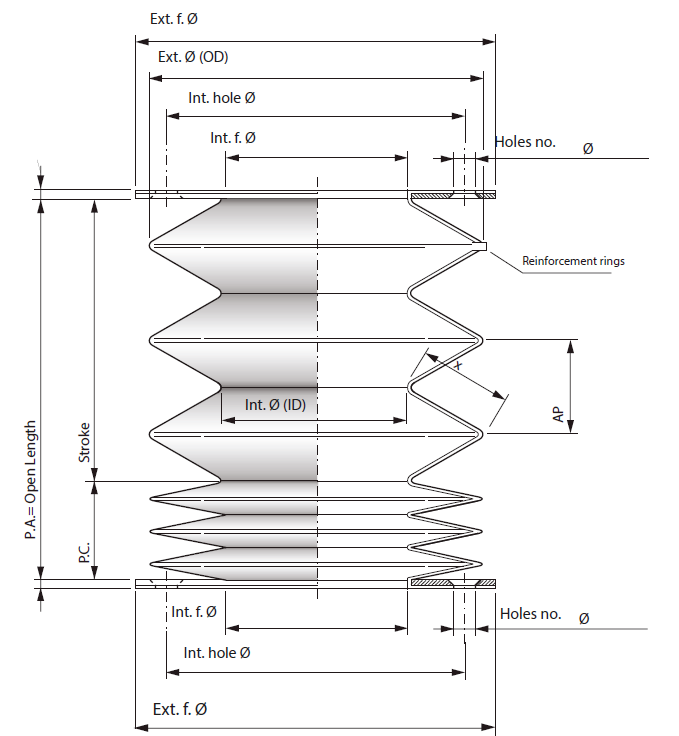

Type C fixing schemes

Bellows with the type C fastening system have two flanges

Bellows data:

Ø e. soff. = Circular bellows outer diameter

Ø i. soff. = Bellows internal diameter

Ø i.f. = Internal flange diameter

Ø int. holes = Flange hole centre-to-centre diameter

Ø e. f = Flange outer diameter

P.A. = Open length

P.C. = Closed length

Stroke = P.A. – P.C.

AP = Open step

X = Bellows fold height

Materials available

- Code PEI: TEMAT 018 Polyester coated in PVC thickness 0.7

- Code PEI: TEMAT 019 Polyester coated in PVC thickness 0.5

- Code PEI: TEMAT 153 POLYURETHANE leaf thickness 0.5

- Code PEI: TEMAT 153/S POLYURETHANE leaf thickness 0.7

- Code PEI: TEMAT 156 POLYURETHANE leaf thickness 0.5

- Code PEI: TEMAT 081 Polyester coated in PVC thickness 0.5 – WHITE

Further materials are available on request: consult our technical department.

Formule

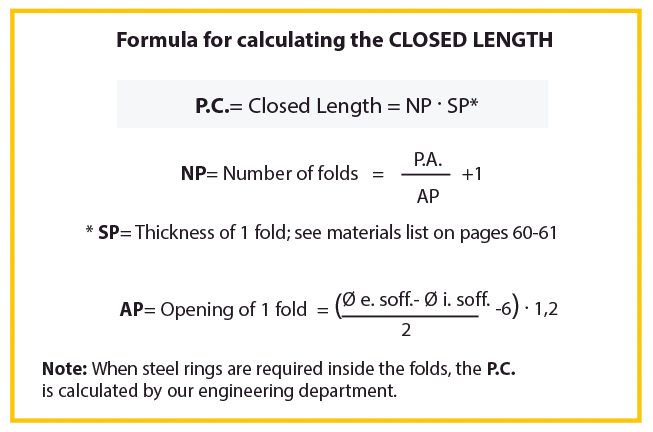

Formulae for calculating closed length

Documentation