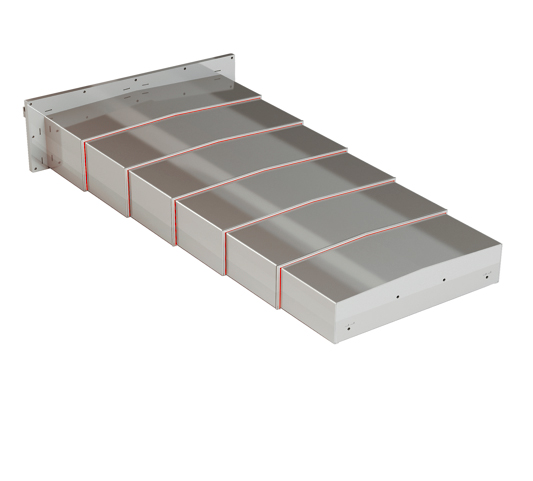

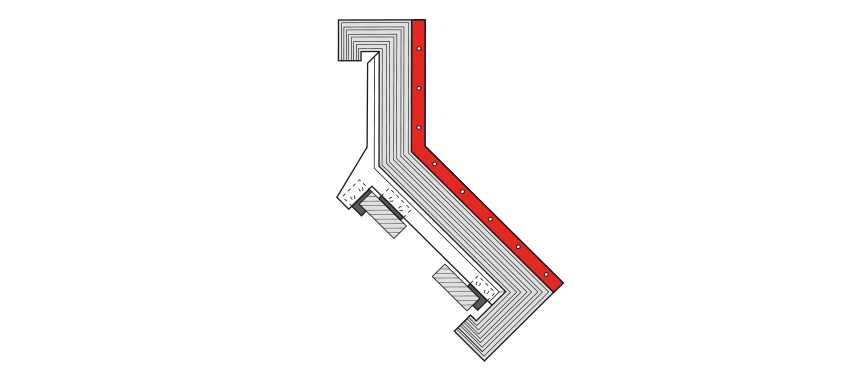

Standard telescopic steel covers

Telescopic steel covers

PEI has reached in a few years a productive dimension in terms of volumes and quality standards, which place it at the top of the market.

Significant investments in machinery and in training programmes for human resources, under the guidance of highly professional technicians, have allowed us to face the real new challenge that the evolution of machine tools places us in front of: the use of linear motors and the increase in axis speeds.

The quality of execution and the attention paid to shock absorbers enable us to solve problems related to high speed.

The steel used is extremely high quality in terms of flatness, corrosion resistance and wear resistance. Sheet thickness ranges from 1.5 to 3 mm.

Telescopic steel covers may also be made of stainless steel. This production requires high quality materials and components, as well as sophisticated production technology. The high speeds of movement demand continuous innovation.

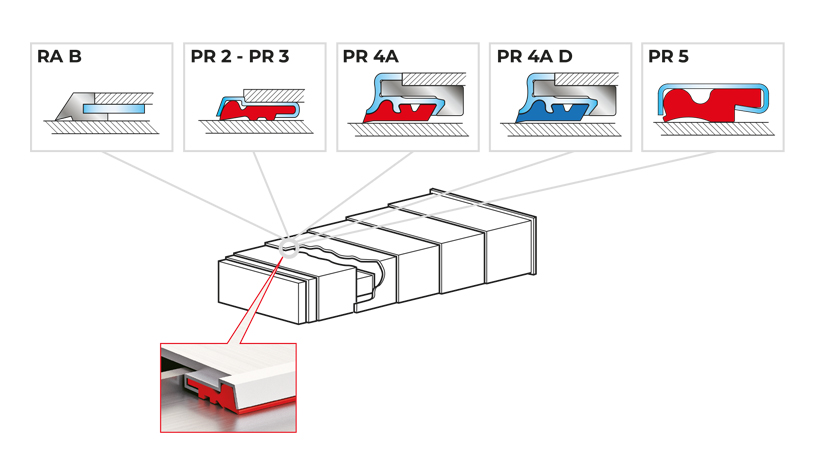

Wipers

Pulling system

Other components

Working positions

Configurations

Documentation

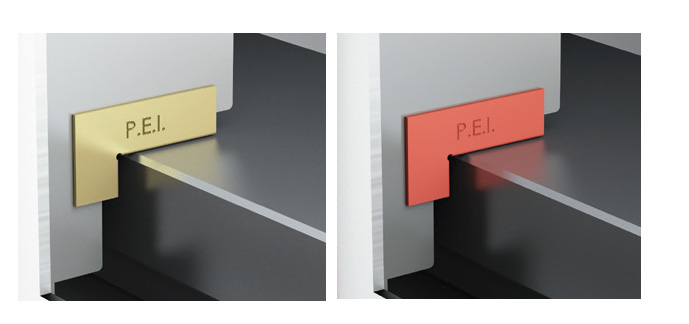

Oil Wipers

Wipers keep the surface clean and prevent chips from getting under the plates.

They are made of polyurethane to resist against heat and coolants, with or without a protective stainless steel chip guard.

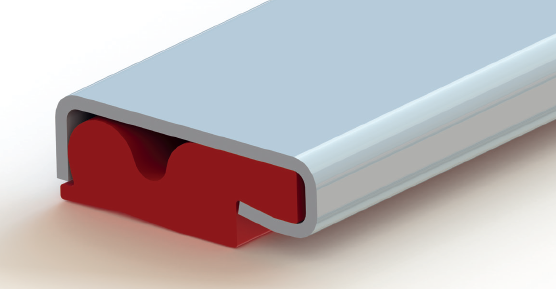

PR5 Oil Wipers

The new PR5 wiper made by P.E.I. is particularly suitable for large-sized telescopic covers.

The gasket protecting and fixing profile is made of stainless steel: it does not oxidise even when not lubricated and resists cold working even with pure water.

Flexible wiper lip for optimal adherence to box to improve protection against chips and coolants.

Precise alignments between the elements keep the wiper preload at the intended value.

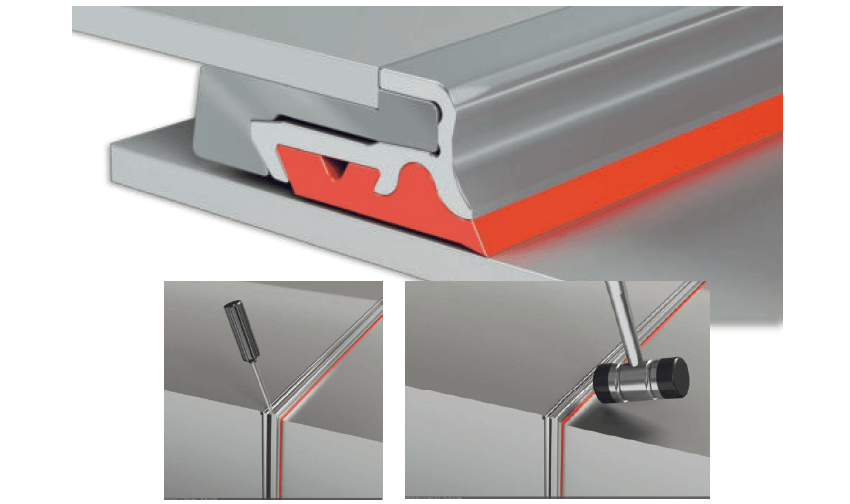

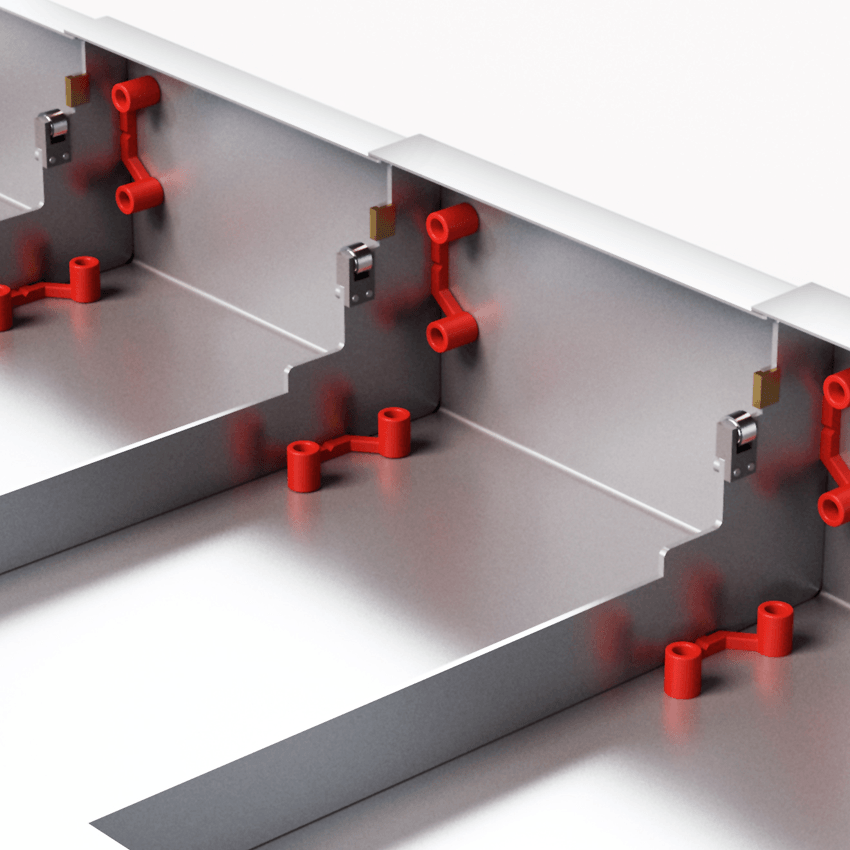

Removable Oil Wipers

PR4A the interchangeable and removable oil wiper

The PR4A Wiper is an innovative solution to replace the wiping profile quickly and without machine stops.

The PR4A Wiper consists of three independent elements:

- a metal profile, integrated with the body of the telescopic cover.

- a second removable metal profile.

- the third is the wiping profile intended for cleaning the cover.

It varies its technical characteristics depending on the working environment for which it is intended, e.g. for working environments with refrigeration liquids or for dry machining in the PR4A D version.

Telescopic covers equipped with the PR4A Wiper allow customers to independently replace the wiping profile by following simple instructions:

- unhook the removable part

- replace the removable metal profile already prepared with the new one

- wiping profile.

Patented

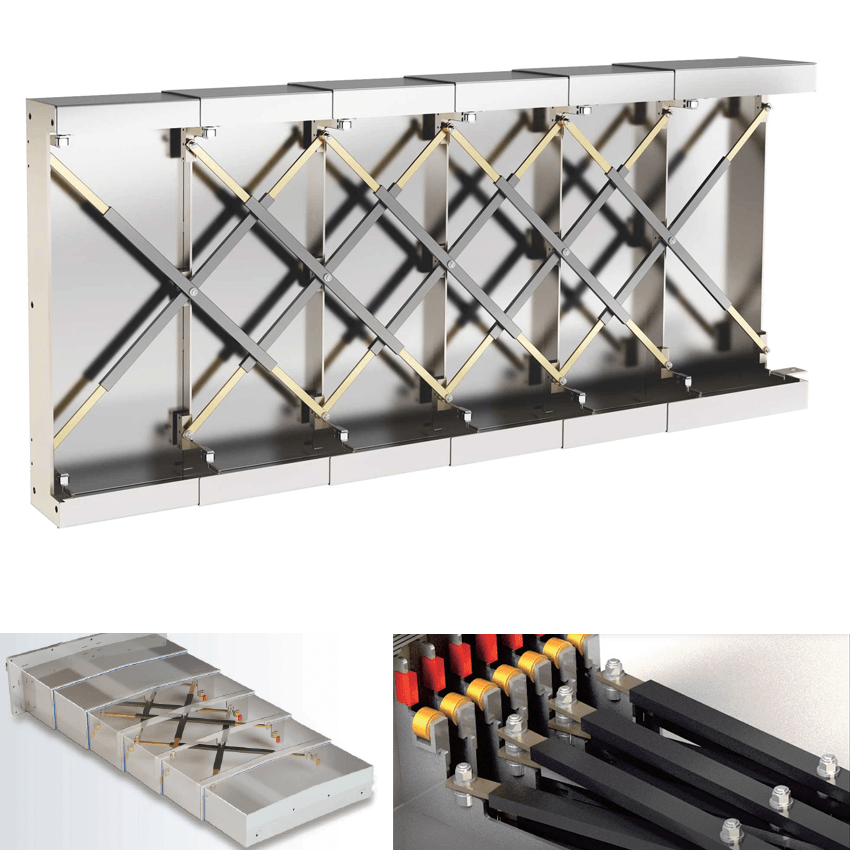

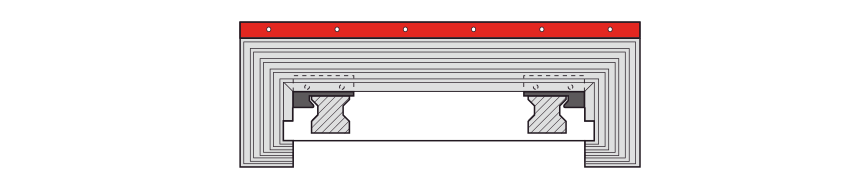

Traditional pantograph

Our traditional scissor system is designed for synchronised movement of all cover boxes of a telescopic cover.

This allows all boxes to move together and evenly.As there is no stop between the cover boxes, the system

runs independently of the drive speed and thus enables high travel speeds.

Proper sizing of the components of the scissor system, as well as proper design concerning dimensions and shape

of the cover boxes, make this system robust and durable.

The machine must provide the drive force to move all the cover boxes simultaneously, even for short strokes.

The pantograph supports constant keeping of roughness in high-finish machining.

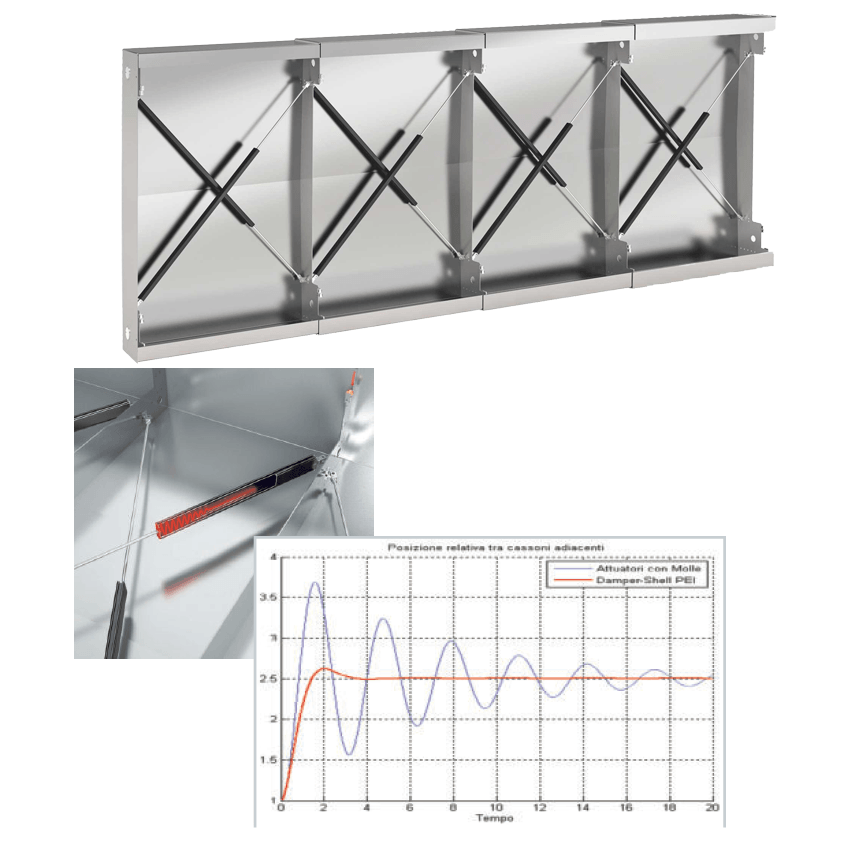

SYNCHRO-TEL TECH

The perfect fit.

The system harmonises opening and closure of medium-sized telescopic covers and is suitable for high speeds and accelerations.

The coupling tolerance between the metal rods is reduced to a minimum.

Unlike a normal pantograph, it can have up to three pivots attached directly to the boxes, thus avoiding vibrations.

Mathematical calculations and operating tests guarantee that SYNCHRO-TEL TECH is the most reliable and durable solution, compared to known synchronisation

mechanisms.

(Patented)

DAMPER-SHELL EVO

Viscoelastic shock absorbers for energy dissipation in large scale telescopic covers working in horizontal and frontal positions.

Made of polymer of a special P.E.I. formulation, it is manufactured in two geometric dimensions.

DAMPER-SHELL guarantees up to 2.000.000 cycles and is ideal for working speeds up to 100m/min and acceleration up to 1g.

Free from boost residue whether the telescopic cover is closed or in resting position, it opens smoothly during expansion without causing friction on the boxes.

This damper is ideal for long strokes being a silent, durable, reliable and maintenance-free solution.

(Patented)

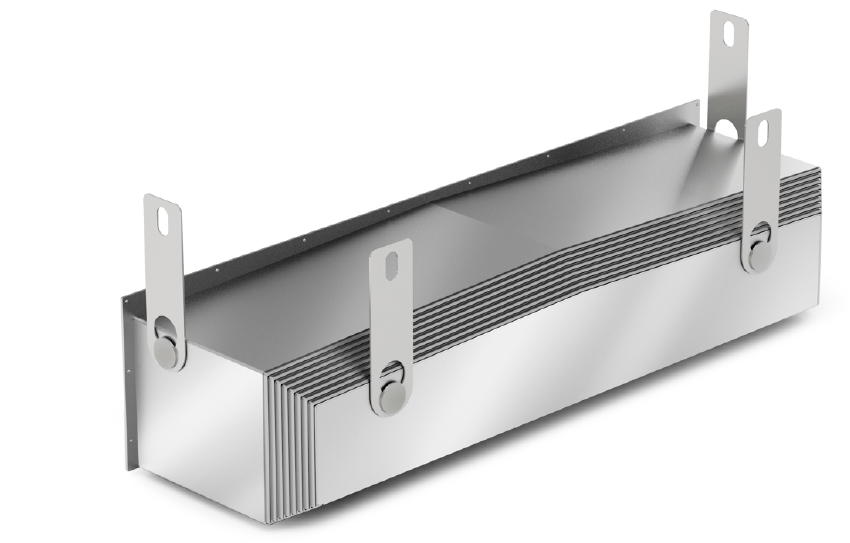

Lifting Systems

Lifting systems can be applied to telescopic covers of various forms and have different characteristics

according to customers’ needs and the weight of the protection.

Shock absorbers

In case of high speed, (patented) shock absorbers reduce noises and oscillations.

Made of polymer that does not deteriorate in contact with coolants.

They are very effective in reducing impact between boxes during movement.

Sliders

Special anti-friction sliders, made of brass or non-metallic material, do not wear out the guideways of the machine on which they run.

Available in many sizes and cross-sections.

Rollers and bearings

Rollers and bearings, in case of high speeds or loads, are inserted to preserve safe and noiseless running.

Both rollers and bearings are assembled on bolted housings allowing correct alignment as well as quick and easy maintenance.

Horizontal

For horizontal working positions. This is the most common solution for small to very large covers with very long travel. Few limits for the shape.

In most cases, mounting in the machine is done by lowering the cover from above, thus handling is easier even in narrow spaces.

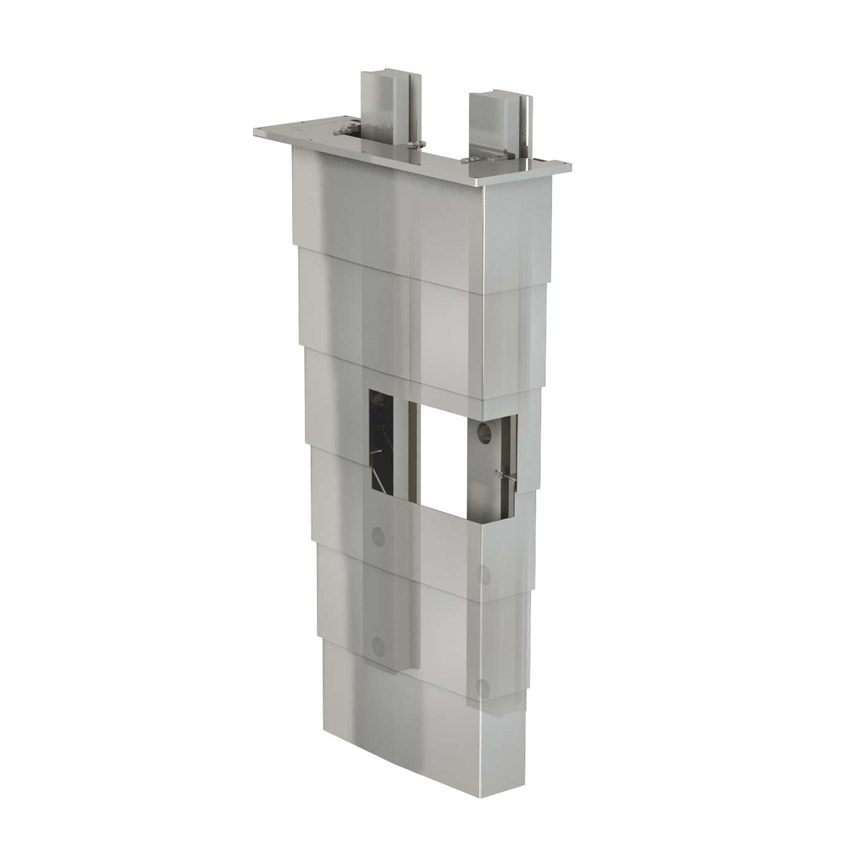

Vertical

For vertical working positions and for small to medium-sized covers.

To prevent the cover boxes from jumping out of the guideways, special retaining slides are mounted to fit exactly the profile of the guideways.

For larger dimensions it is possible to fit retaining slides that allow the cover to be mounted directly onto the guides from the front, without inserting it.

If desired, plates can be worked out inside the cover particularly to prevent lubricants from leaking onto hydrostatic guides.

Transversal

For frontal working positions and in case of small to large covers.

To prevent the cover boxes from jumping out of the guideways, on the upper side special retaining slides are mounted, designed for fitting exactly the profile of the guideways.

Depending on the space available and the shape and position of the guides, the cover can be mounted frontally from above or it may be necessary slided onto the guides.

In case of frontal covers between two carriages, their design must consider the frontal mounting from above.

Multi-axis for lathes

Telescopic cover for lathes Z-axis or axes that run parallel to the Z-axis, such as counter spindles, lathe centres and steady rests.

Based on the axis involved, the shape of the telescopic elements, the shape and position of the guides, mounting can be done from the frontor it may be necessary to slide the cover onto the guides.

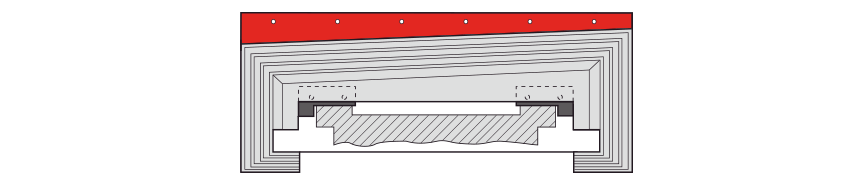

Form 1

Form 1: economical, for small and medium sizes, even for long runs.

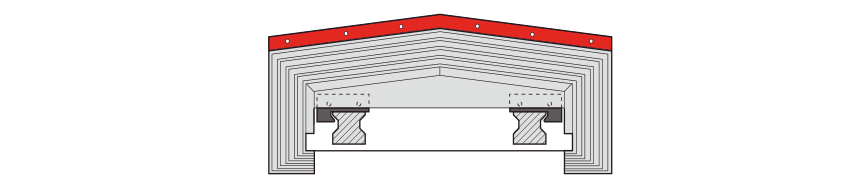

Form 2

Form 2: economical, for small and medium sizes, it allows more useful space for the workpiece that can take advantage of the free volume left by the inclination of the boxes, as on large parallel lathes.

It allows you to direct the coolants and the shavings towards the collection device. Even for long runs.

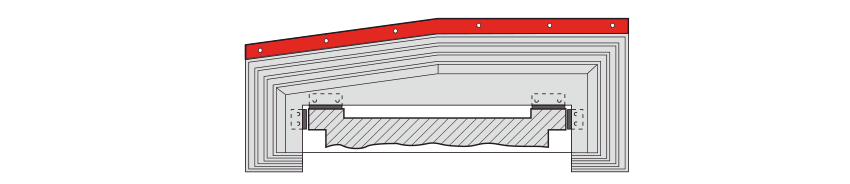

Form 3

Form 3: the double inclination stiffens the sheets of the boxes, allowing a high and long-lasting scraping of the telescopic elements, avoids the stagnation of coolants and shavings, giving longer life to the oil scraper seals.

Suitable for small to medium and large sizes, even for long runs.

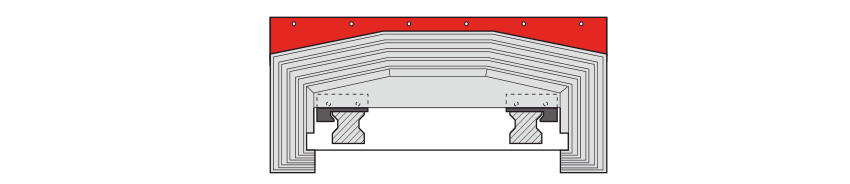

Form 3 variant

Form 3 variant: the asymmetry of the form is combined with the advantage of the double inclination that stiffens the sheets of the boxes, allowing high and long-lasting scraping of the telescopic elements, which leads to a greater useful internal space to contain energy chains, or other devices placed parallel to the machine axis.

Suitable for small to medium and large sizes, even for long runs.

It allows you to direct the coolants and the shavings towards the collection device.

Form 4

Form 4: the triple pitch leads to a high rigidity of the caissons and allows the construction of wide covers with excellent scrapability of the telescopic elements.

Suitable for medium, large and very large sizes, it allows long strokes.

It supports the large quantity and weight of the chips well.

For lathes

For lathes: traditional cover for the axes of lathes with an inclined guide surface, allows ample space for the workpiece, integrates well with the covers of the tailstocks, steady rests and counter-spindles, creating favourable labyrinths to prevent the entry of even the smallest ones.

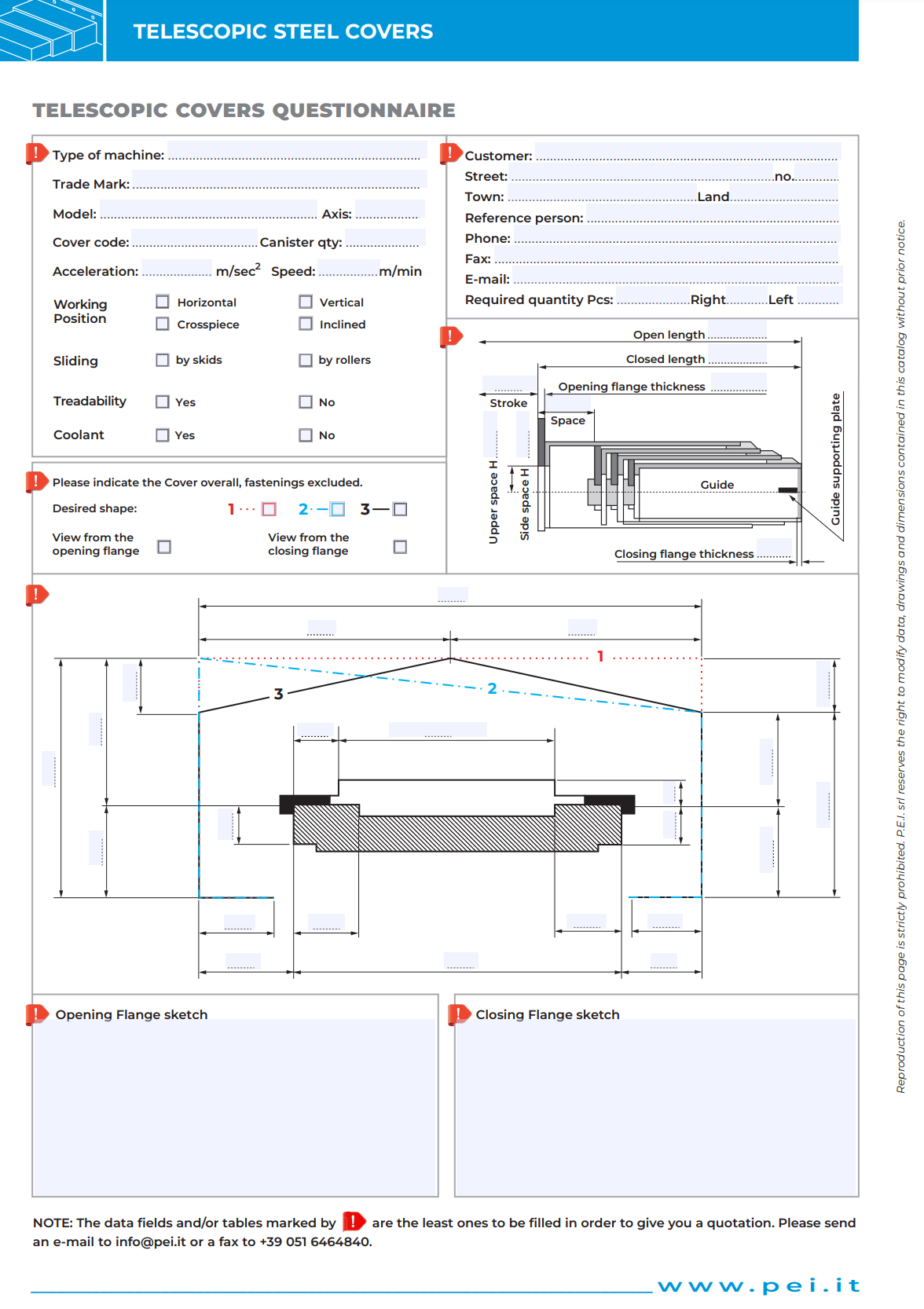

Telescopic cover questionnaire